Automated solutions that can help companies in Africa maximize opportunities in

both local and export markets will be the key theme of Ishida East Africa’s

participation at the Propak East Africa 2023 exhibition.

With businesses needing to increase efficiencies and throughput in order to remain

competitive while still delivering the high-quality products being demanded by both

retailers and end-consumers, Ishida will showcase its latest developments in

weighing, packaging and quality control equipment.

Providing value for money positioning while still incorporating several advanced

features for enhanced performance, the solutions offered by Ishida enable

companies of any size to reduce costs, minimize waste, and increase speed,

efficiency and consistency in the food packaging process. This helps them to

maximise yields while delivering the highest quality packs to their customers.

Visitors will be able to see the equipment in action, and Ishida experts will be on

hand to discuss individual customer requirements.

X-ray inspection systems can play a vital role in allowing companies to meet the

strict quality compliance standards of different countries, carrying out a thorough

inspection of every pack that includes foreign body detection as well as identifying

damaged product or packaging or missing items, weight estimation and counting

components.

From its comprehensive quality control portfolio Ishida will demonstrate the IX-EN-

4093-S entry-level X-ray inspection system, which combines impressive sensitivity

with minimal operating costs. The machine incorporates Ishida’s unique Genetic

Algorithm (GA) image processing technology which delivers superior inspection

sensitivity. It can reliably detect foreign bodies including steel, aluminium, tin, glass,

stones, dense rubber, plastic, bones and shells for unrivalled food safety in a wide

range of packaged and unpackaged food products.

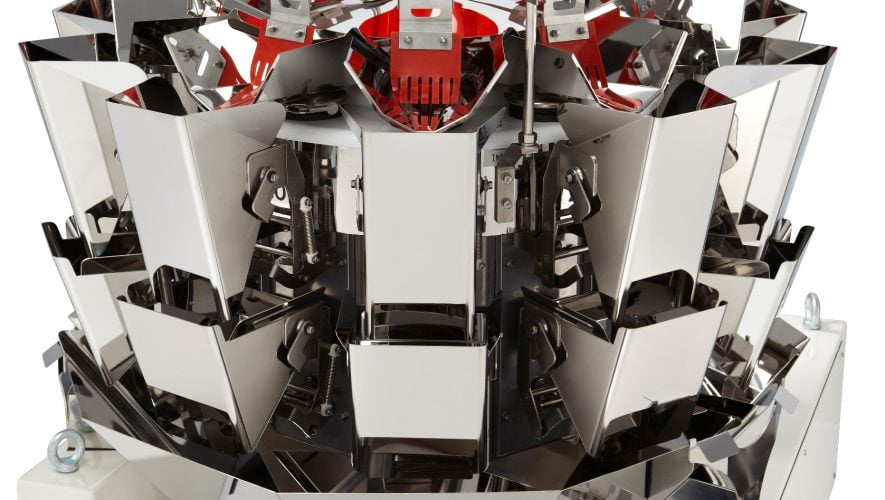

Another highlight of the stand will be a complete packing line for snacks, offering

manufacturers a single-source solution that will help them to produce accurately

weighed, quality packs quickly and efficiently. Central to this is Ishida’s CHW &

ASPEC Snacks Packing System. The economical and reliable weigher and

bagmaker combination incorporates Ishida’s proven multihead weighing and

bagmaking technologies to provide an economical investment that can deliver a fast

payback of typically less than a year.

The system offers weighing and bagging speeds of up to 90 packs per minute with

high efficiency and close to zero product and film waste. It can handle free flowing

snack foods such as chips, nuts and seeds in a variety of bag formats, including

pillow, gusseted, block bottom and perforated cut. The hygienic, easy clean design

ensures user-friendly operation and fast and simple product changeovers.

Ishida has a dedicated office in Nairobi to provide sales, service and spares support

to companies through the East African region.