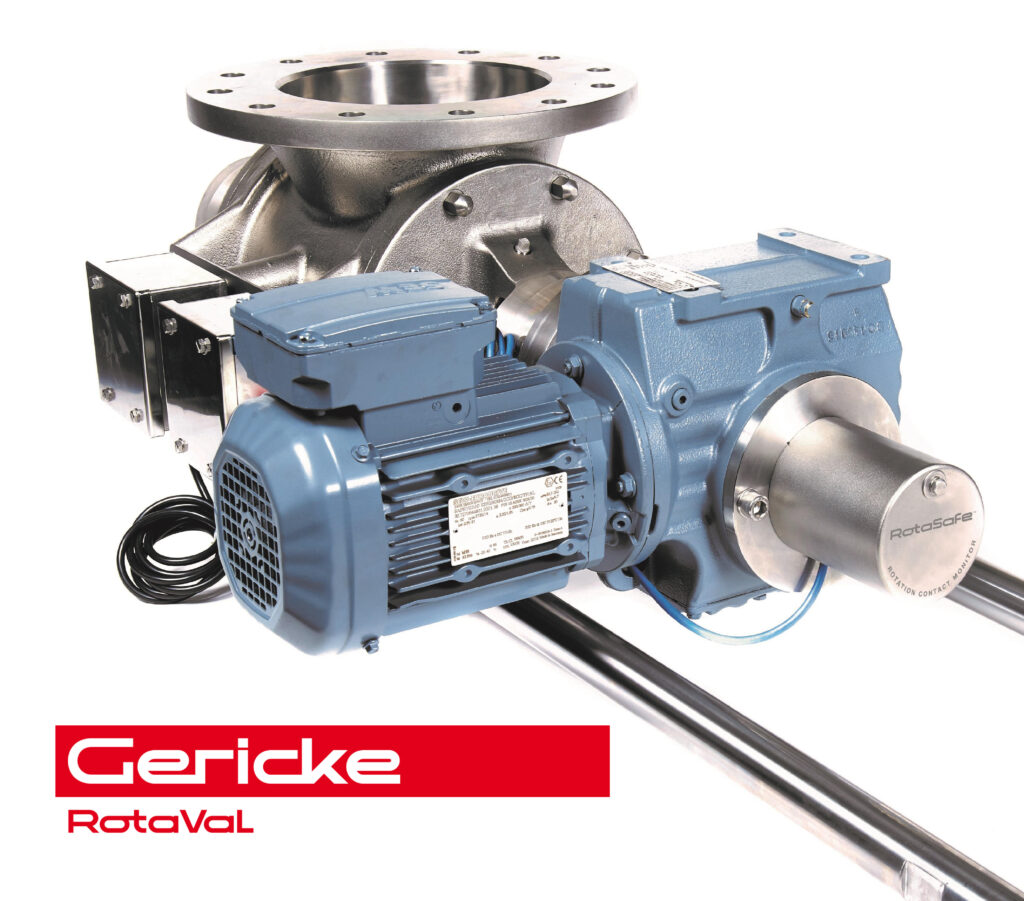

Gericke RotaVal have launched an enhanced version of their class leading RotaSafeTM system for their rotary valves. Designated the RotaSafe RS1 it has been developed in close cooperation with key customers.

The rotor protection system RotaSafe is designed to instantly detect any contact between the rotor and valve housing while at the same time sending a signal to the control system to isolate power to the drive motor. It will primarily be of interest to customers where product contamination due to metal to metal contact is a significant issue.

For many years Gericke RotaVal has continuously improved its foreign body and contact system. This latest version provides additional functionality, flexibility, and optimized responsiveness for the end user. The first systems have been delivered and are in full operation, protecting the process equipment and the products.

The Swiss Gericke Group has been designing and manufacturing equipment and systems for modern

bulk material processes, as well as providing design and consultation services, for more than 125 years. Gericke bulk materials processing technology can be found throughout the world in many sectors including the food, chemical, pharmaceutical, plastics and construction material industries.

Gericke’s fully owned group companies employ more than 300 experienced professionals and are located in Switzerland, Germany, Great Britain, The Netherlands, France, USA, Brazil, Singapore, Indonesia, Malaysia, Thailand and China.