The year 2023 opens with major international events, including Fruit Logistica, the leading event in the fruit and vegetable sector. The trade fair is dedicated to the entire supply chain: from fresh produce, to processing and end-of-line technologies, through to services and logistics.

The appointment, as per tradition, is in Berlin from 8 to 10 February at the Messe Berlin exhibition centre: the last edition registered more than 40,600 visitors from 132 countries; the next one will welcome around 2,000 exhibitors divided into themed pavilions. Thanks to a rich programme of conferences and workshops, Fruit Logistica has always been perceived as a decisive event for taking stock of market scenarios, innovations and challenges on a global level.

Robopac will be present in Hall 6.1, Stand A-42 with some of the best end-of-line solutions for the food industry. A sector of primary interest for the Aetna Group and its companies, which have always dedicated resources and investments in research and development to optimize their technologies and calibrate them to the real needs of the market. The dedicated stand will be manned by specialized Robopac personnel, who will be on hand to offer advice and answer all visitors’ questions on process techniques and technologies for optimizing the packaging phases.

The stand will feature the Robot S7, a self-propelled packaging machine with high packaging autonomy, equipped with the R-Connect connection system, which allows complete control of machine operation and total support to the end customer.

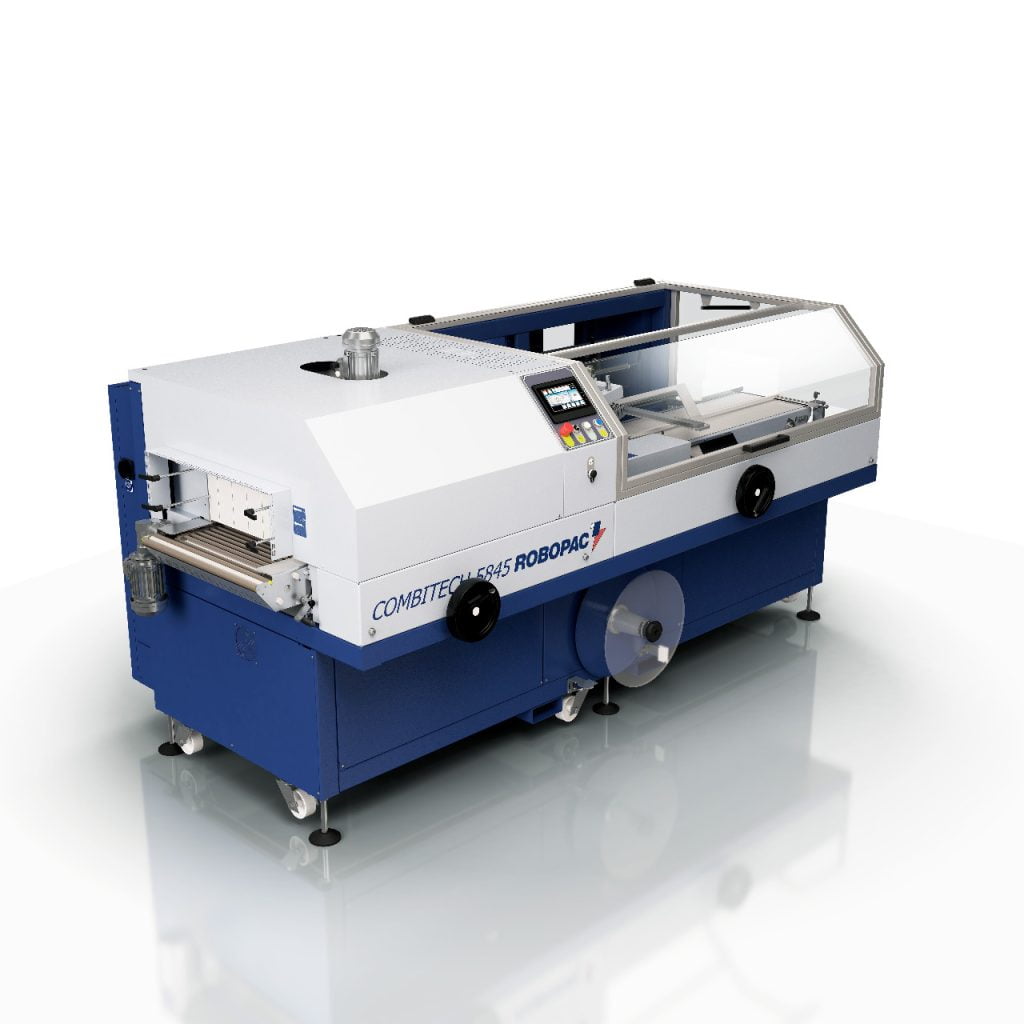

We then move on to the Combitech 5845, the shrink wrapping machine suitable for packaging various types of products. Precise and versatile, it offers practicality and safety of use for the operator, features that determine its competitive advantage and strong production adaptability.

Next up, Wrapman, the manual wrapping machine ideal for packing loads of any weight, size and shape,

guaranteeing maximum protection and stability of the load. Wrapping with mesh film, for products that require transpiration, will be on show in Berlin.

Regarding the stabilization of unstable loads, Robopac offers Masterwrap HD Plus XL, a semi-automatic wrapping machine equipped with a rotating arm.

Rotoplat 308 LP, the rotary table for wrapping products vertically with stretch film and reduced thickness base, thanks to the reduced dimensions of the new ramps, is a space-saving solution: it facilitates loading operations and avoids accidental collisions with the forks of the forklift.

Last but not least, ReCYCLE, the latest generation eco-friendly solution dedicated to waste disposal, will not be missing again this year. With a 70 % reduction in starting volume, this machine facilitates the transport and handling of waste material.

It should be noted that Robopac wrapping solutions are compatible with all types of stretch film on the market and therefore also with the new fully composable films. These films, which comply with European UNI EN 13432 and North American ASTM D6400 standards, combine the characteristics of biodegradability, transparency, elasticity, breathability with the mechanical resistance typical of plastic materials. After use, this film is sent for organic recycling through the domestic or industrial composting stream, avoiding the lengthy and costly processes associated with sorting and recycling post-consumer plastics, as well as the incineration of undifferentiated waste.