Siemens Smart Infrastructure introduces its new natural agent extinguishing portfolio, Sinorix NXN. Focusing on the protection of lives, assets, and business continuity, the new fire extinguishing portfolio combines simplicity with advanced technology to modernize traditional fire safety. The agents consist of the natural gases argon, nitrogen, and carbon dioxide. They are ideal for specific application areas such as storage rooms for chemicals (argon), critical electrical infrastructure (nitrogen), or unmanned areas (carbon dioxide). The new Sinorix NXN portfolio uses only agents and compounds that are naturally found in our atmosphere and do not harm the environment. It also has a reduced ecological footprint, thanks to its compact and versatile product design.

Environmentally-friendly and sustainable portfolio

The new Sinorix NXN extinguishing agents are chemically inert and do not create harmful reactions or byproducts in contact with fire. Even in case of an incident, the activated extinguishing agents do not leave any residue behind for clean up or disposal and therefore ensure a rapid resumption of business operations. Inert agents have poor electrical conductivity properties making them ideal in any application where protection of mission-critical infrastructure is important. Argon, nitrogen, or carbon dioxide offer excellent extinguishing properties for fire Classes A (solids), B (flammable liquids), and C (flammable gases), whereas argon is optimally suited for fire Class D (metal fires) and nitrogen for Class E (electrical fires). The new Sinorix NXN natural extinguishing agents feature zero ozone depletion potential (ODP) and they are not subject to regulatory restrictions or phaseout. In addition, the extinguishing products follow EN standards and guidelines and are backed by appropriate certifications, including VdS and CNPP to ensure the sustainability of the extinguishing solution.

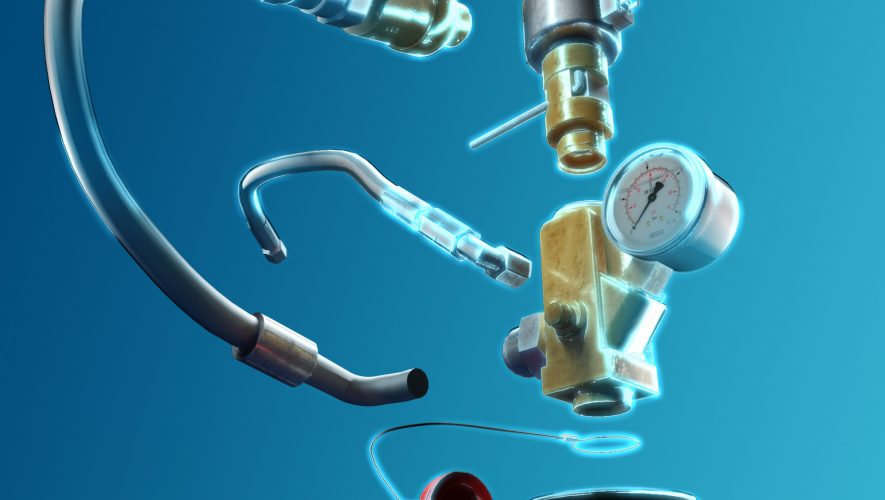

New design concept

The new ADVtechnology (Advanced Double Actuation Valve) by Siemens saves costs and increases efficiency through all lifecycle phases of a fire extinguishing system. The product portfolio has been simplified by introducing multi-use components that are the same for all agent types. Furthermore, only one type of pneumatic actuator is now used for all pressure ranges (8-360 bar) and only one type of cylinder valve is used for both electrical and pneumatic actuation. This makes the design process more flexible and efficient (for example, calculations for new configurations or new agents are made more quickly). With the help of the ADVtechnology, cylinder exchange, as well as the time needed for installation, has been drastically improved. Now users can install and maintain an extinguishing system more easily and much faster.

Building lifecycle support

In addition to local representation, Siemens operates a Competence Center in Vienna and a testing facility in Switzerland, where new and special extinguishing solutions are tested and improved. These facilities provide specialized expertise for new and highly challenging applications. Additionally, Siemens supports the full building lifecycle with the latest digital tools including specification texts, BIM data, as well as online product selection, configuration, ordering, and online calculation tools. Access to Siemens expertise, design know-how, and experience avoids over-engineering and minimizes project costs while increasing fire safety. The new Sinorix NXN extinguishing systems are developed for easy integration in complete fire safety solutions, including fire detection and evacuation to increase safety and reduce risks. This integration also optimizes facility management by enabling cloud-based, digital services that substantially reduce operational and maintenance costs.