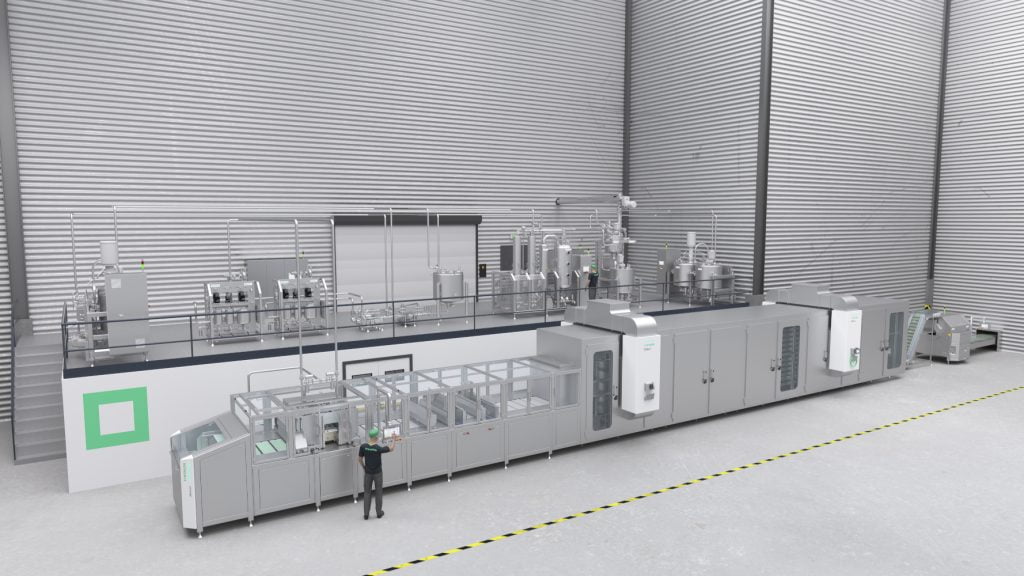

Closed production process with innovative kitchen, depositing, and oiling

technology

• Designed for special requirements in the production of functional gummy and

jelly products

• Smooth processes thanks to high automation levels and digital monitoring

solutions

With the new turnkey line NutraFlash, the Syntegon subsidiary Makat Candy Technology sets new standards in the starchless production of gummy and jelly products. Manufacturers can increase the quality of sensitive products with upgraded kitchen, depositing, and finishing technologies.

Besides producing gummies and jellies with high dry substance content and dosing

ingredients precisely, the new line enables accurate starchless depositing in reusable

plastic molds. The holistic turnkey approach ensures a highly reliable, closed

production for consistent product quality along the entire process. To this effect, the

system includes end-to-end recipe management and a coordinated control concept

for harmonized operations.

“Our line covers all steps of jelly production from dosing and mixing the ingredients to

product finishing,” explains Dr. Sandra Link, product manager at Makat Candy

Technology. The starchless technology plays an increasingly important role in the

production of so-called nutraceuticals. These highly sought-after functional sweets

contain valuable ingredients such as vitamins or minerals. As a consequence,

nutraceuticals require special handling along the entire production line, for example

precise dosing to ensure the right additive content per individual piece. Makat relies

on proven technologies for all process steps. The new turnkey line allows for even

smoother production thanks to comprehensive adaptations. “Our high degree of

automation combined with digital condition monitoring helps manufacturers to achieve

reliable and time-saving processes with low reject rates,” Sandra Link explains.

Two-step dissolving process with Rapidsolver Solids +

The Makat Rapidsolver Solids + is at the heart of the starchless kitchen. As a special

execution of the proven Rapidsolver, the system achieves high dry substance content

of up to 86 percent when dissolving the base jelly mass – a special characteristic of

starchless production. It eliminates the need for subsequent moisture removal by

means of starch, as is the case with starch-based depositing in a mogul line. “This

significantly reduces process times and enable manufacturers to produce gummies

and jellies in a time- and cost-efficient manner,” Sandra Link emphasizes. Adding

supplements is another special feature in the production of nutraceuticals. The often

sensitive ingredients are optimally protected from excessive thermal stress since functional additives are only added shortly before depositing and the dwell times in the depositor are kept short.

Tailless depositing with the CMP Special tail-cutting nozzles of the CMP depositor ensure a high-quality processing, even of highly viscous and difficult jelly masses. Once the products have been

deposited into reusable plastic molds, they cool down in the line’s integrated cooling

tunnel. This spares manufacturers additional handling processes, such as removing

the molds and cooling the products in external cooling chambers.

achieves high dry substance contents. This results

in shorter process times and time-efficient gummy

and jelly production.

Flexible product finishing with the BC 96

The application of polishing agents in the fully automated BC 96 oiling drum has also

been adapted significantly: in addition to a centerlining functionality for lower process

variability, the drum features a Human Machine Interface (HMI). This allows operators

to enter individual target values for each product recipe and call up the data as

required. This way, the BC 96 ensures consistently high quality during the oiling

process in addition to fast product changeovers and product-specific oiling.

Continuous condition monitoring

Sensors facilitate preventive error detection at the oiling drum and at several other

process steps of the turnkey line. Integrated software immediately detects deviations

and reports them to the operator via status lights at the line’s respective production

stations, as well as via HMIs. “Thanks to these status updates, operators can

promptly initiate troubleshooting and safeguard the availability of the entire line,” Sandra Link explains.

Monitoring, line control, and cleaning are based on a uniform concept: the recipe-

controlled approach covers all production steps and ensures both consistent results

and fast and easy product changeovers. CIP (cleaning in place) cycles for the kitchen

and the depositor offer different cleaning modes, while the line’s hygienic stainless

steel design enables fast and thorough cleaning – for the safe production of gummy

and jelly products. In addition, the entire line is designed for contamination-free

product handling, thus the line’s closed loop eliminates for example the need for

manual mold handling.

Support from the Application Technology Center

Starchless nutraceutical production not only provides many advantages; it also poses

numerous challenges. Manufacturers need to precisely coordinate the complex

interplay of ingredients, formulations, and processes. Makat Candy Technology

therefore offers comprehensive support for the demanding production of various

gummies and jellies. At its own Application Technology Center in Dierdorf, Germany,

the company also works with its customers to develop individual products and

processes that support successful and efficient starchless production.

kitchen, depositing line, and product finishing for

precise starchless production.