The aseptic packaging market is estimated to grow at a CAGR of 10.89%, from $39.6 billion in 2017 to $66.5 billion by 2022. The growth is mainly driven by the rapid expansion of end-use industries such as food & beverage and pharmaceuticals across China, India, Brazil and South Africa. Primary factors pushing the field upwards are the rising demand for convenience and quality products, a change in consumer lifestyle, the growth of the dairy beverage market, and last but not least, a steady increase in purchasing power in the Asia-Pacific region, which in 2019 accounted for the largest market share – 53.61%. Indeed, progress in developing countries inflates the demand for packaged food & beverages as well as natural products such as flavoured milk and juices.

As of today, the main segment is food and dairy, with a 57% share. Consumption-wise, cartons are the most common packaging material in the aseptic beverage market (51% share) as well as in the entire sector of aseptically-packaged products (72% share).

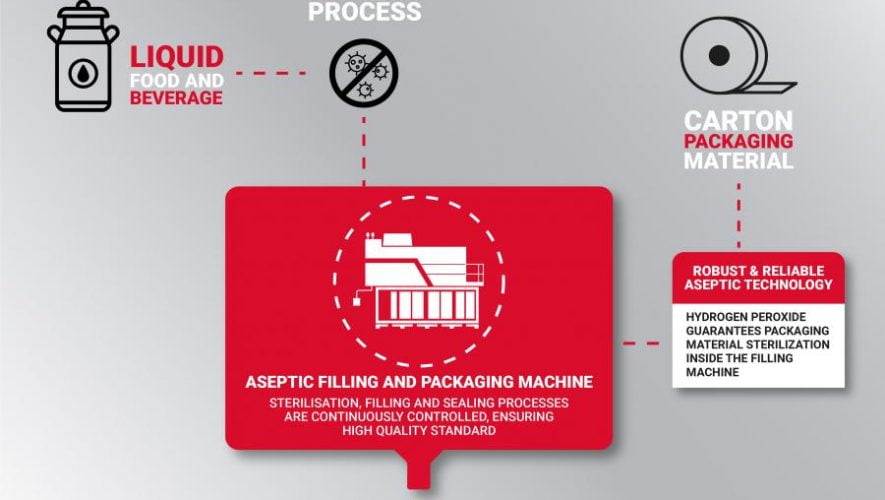

Operating principles

Aseptic packaging consists in the process of aseptically packing food & beverage and pharmaceutical products right after sterilisation, executed through UHT (Ultra High Temperature). This is different from the standard process, where sterilisation is performed after packaging rather than before.

In addition to sterilisation, another factor that significantly impacts shelf life is the material in use. In this regard, the most common one is polylaminate, also known as multilayer aseptic carton. Polylaminate is crucial, as it decreases the exchange of oxygen with the environment while also working as a barrier against light – two elements that, if they both came into contact with the product, might negatively alter it.

Carton bricks guarantee several advantages over traditional milk packaging methods. For one, they do not need refrigeration, since the aseptic packaging process ensures long shelf life at ambient temperature. Also, their characteristic brick-like shape makes them easy to stack and space saving. These factors among many others determined the ballooning popularity of aseptic carton packaging, which, as of today, holds an important share in the UHT milk market.

In this white paper we are going to provide a 360-degree analysis of aseptic packaging with a particular focus on multilayer aseptic carton bricks for food & beverage products.

The advantages of multilayer aseptic carton

Multilayer aseptic carton delivers many advantages from a business, consumer, and marketing perspective.

Business-wise:

- It ensures a long shelf life at ambient temperature.

- Contrary to in-container sterilisation, it maintains the food nutritional and sensory properties.

- It is space saving, and therefore more cost-efficient in terms of storage space.

- It is more energy-efficient to produce.

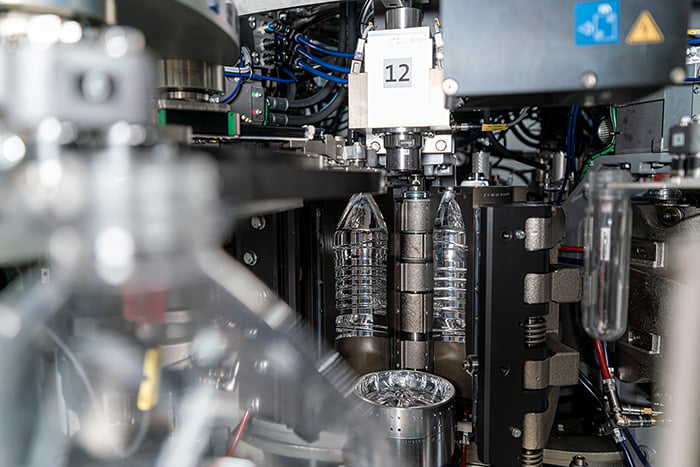

- The package can be formed simultaneously with filling through a single form-fill-seal process.

- It protects the product from contamination.

Consumer-wise:

- It offers the highest degree of protection.

- It is light, easy to baggage, and safe.

- It is easy to stow and to stack.

- Disposal is a non-issue, since a multilayer aseptic carton is foldable.

- It provides a large area that can be exploited for marketing information and branding.

- Last but not least, it has a distinctive “eco-friendly” feeling.

Marketing-wise:

- It provides a large area for graphics that can be exploited for branding.

- The brick’s shape can be irregular, so as to perfectly fit the brand identity.

- It is eco-sustainable, and sustainability sells.

This definitely be the next preference. You are perfect, theme team. I Really enjoy the system, fonts along