New US plant to boost production of its paper sidestream-sourced barrier coating to serve the Americas

Green-tech start-up Melodea, Ltd., producer of sustainable barrier coatings for packaging, announces plans to expand its eco-friendly solution to the U.S. market. The move is set to support the increased production capacity of its novel, plastic-free, plant-based barrier coatings to serve the burgeoning US and South American markets. Melodea will showcase its portfolio of products at the PackExpo exhibition in Chicago on 23rd to 26th of October, Booth #27075.

One of the greatest strains on the ecology and climate is plastic waste. Of the millions of

tons of plastic waste generated each year, single-use plastic packaging is the worst culprit.

Melodea produces barrier coating material sourced from wood pulp, a sidestream of the

paper-making industry. Its innovative green solution is helping food, beverage, and

consumer goods packagers sever unwanted ties with plastic. Plastic has long been necessary

to maintain food freshness, acting as a barrier to prevent unwanted transmission of oxygen,

water, oil, or grease into the products.

Novel use of forestry by-products

Melodea developed a unique formula derived from cellulose nanocrystals (CNC) that can

withstand high humidity and protects packed products from oxygen, water, oil, and grease.

This sturdy but lightweight plant material offers an alternative to plastic and aluminum for

maintaining the quality and integrity of packaged foods. As a forestry by-product, it also is

biodegradable, fully recyclable, and non-toxic to people or the environment. The award-

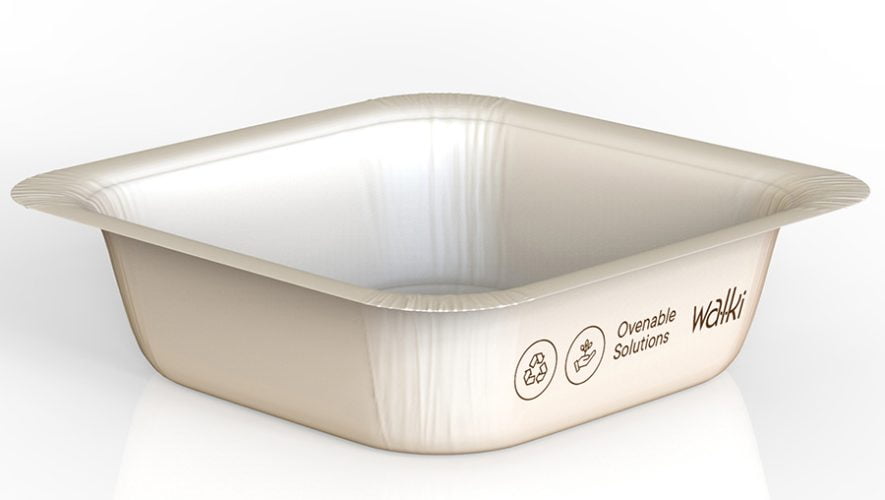

winning material currently is being used for the manufacture of paper-based pouches, lids,

molded pulp trays, and more.

In line with increasing demand from the US market, Melodea will operate a toll

manufacturing plant in the US which will allow for the cost-effective production, shipping

and easier logistics of its two leading products: MelOx™, which protects packaged products

from oxygen and oil and grease transmission; and VBcoat™, which counteracts the

transmission of water, oil, and grease. All of Melodea’s barrier coatings are in compliance

with FDA regulations for food packaging

“CNC from naturally abundant and renewable cellulose is emerging as one of the most

promising green solutions to help replace environmentally harmful materials,” enthuses

Shaul Lapidot, CEO and co-founder of Melodea. “The new plant, combined with our newly

established ties in the US, can potentially triple our manufacturing capacity to meet

amplified demands. It also will shorten the travel and subsequent carbon footprint by

bringing production closer to our main markets in South America and the US.”

Melodea recently forged a new commercial deal with a major manufacturer of plant-based

fiber solutions in its mission to eliminate single-use plastics. The company will produce and

market various packaging products infused with Melodea’s VBcoat moisture barrier. The

first product to be rolled out is an eco-friendly, high-performing molded pulp tray for leafy

greens designed to replace existing plastic-based formats.

Melodea estimates it will be ready to start shipping locally from the US site within the next 3

to 6 months as it initiates production of its novel barrier coatings with a local US partner.

The new pipeline will serve its current North American clients (including leading food and

consumer goods companies) and further expand its client network.

CNC growth trajectory

The global nanocellulose market is currently worth approximately US$346M and is

projected to grow to US$963M by 2026. Driven by consumers’ demands for eco-supportive

packaging solutions, nanocellulose is gaining traction among retailers differentiating

themselves by decreasing the impact of their products on the environment. North America

boasts the highest market share of the global flexible packaging market, with some of the

largest international market players in the field of paper-based packaging headquartered

there.

Melodea has so far raised a total of US$20M in capital. The company wasy founded as a

spin-off project initiated at the Hebrew university of Jerusalem in 2010 in Israel by Dr. Shaul

Lapidot together with Tord Andres – an expert from the composites world, and Oded

Shoseyov PhD; – a renowned expert in Nano materials and plant biotechnology who sits on

the Melodea advisory board. Melodea’s technology is protected by an impressive 14 patents

and was a winner of the Packaging Europe 2019 sustainability award.

“CNC is the ideal environmentally sound solution, delivering high-performance ‘clean and

green’ paper-based packaging products,” explains Zvika Weiss, CFO of Melodea. “Our CNC is

sustainably produced, recycling about 95% of the materials in the process, and its superior

performance has been verified by academic research. CNC has great potential to turn the

tide on the cascade of negative impacts from plastic pollution that have been a pressing

environmental issue for too long.”