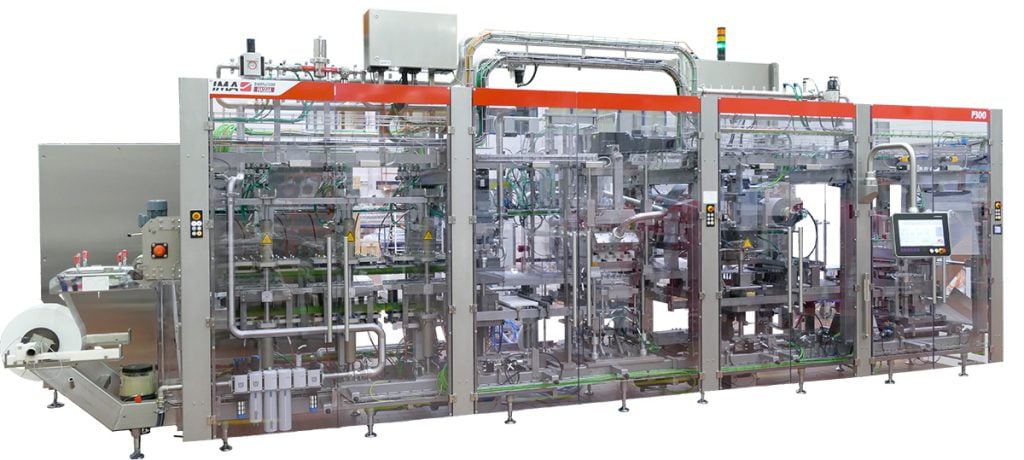

Mills in Fredrikstad is a long lasting customer of IMA Hassia. The first machine for thermoformed portion packs was installed in 1987. In February a FFS machine ‘P300’ to produce PP portion cups of margarine for professionals has been delivered and is in production since a few weeks.

The market for portion packs continues to grow rapidly. As they may be used for a wide range of applications, they are extremely easy for consumers to handle.

To meet the growing market demands from professionals for margarine in portion packs and to be able to use a more sustainable packaging material – PP material for bottom foil and lid – Mills decided to invest in a new machine.

The portion pack machine from IMA Hassia is filling margarine in rectangular cups with possibility for three different filling volumes (10g, 15g, 25g). The machine is equipped with the patented cutting tool of the ZERO Technology range from Intecma. Due to this punch it is possible to separate PP cups easily into single cups. This was the perfect solution to fit into Mills plans for more sustainability.

Mills is a Norwegian family-owned house of brands, established in 1885 at Grünerløkka in Oslo for margarine. Mills is part of the Agra Group, one of Scandinavia’s largest branded food groups with companies located in Norway, Sweden, Denmark and Poland.

Mills has a workforce of 450 employees and produces about 50,000 tons of food per year for households and commercial kitchens in Norway and abroad. The product range includes animal or vegetable oils and fats, prepared or preserved fish, caviar cream, plant mayonnaise, spreads, deli-salads, … The largest production facilities are in Fredrikstad and Drammen.

“We are very satisfied with the consumer friendly packaging solution this machine offers for our margarine.” reported Per Johannessen, Project Engineer Technical Department of Mills. “IMA Hassia is a trusted partner and has a high competence in PP material which enables us to fill our products into more sustainable material. And when we decided to buy a new machine, IMA Hassia was able to deliver a P300 machine with a very short leading time.

Because of the Covid 19 travel restrictions it was not possible for us to visit Hassia Verpackungsmachine factory, or do some other reference visits before we signed the contract. We therefore have to put all our trust in our own experience, that we have after using Hassia machines for decades for filling margarine.

The machine also has to be modified to fit our production areas, so it has been necessary with a lot of communication during this project via E-mails and video conferences. All of that communication has been handled very good from Hassias Project Manager and his staff.”