Cortec ® is pleased to announce that its Cortec ® Coated Products (CCP) division in Eau Claire, Wisconsin, has won the Wisconsin Recycling Excellence Award! CCP is one of 11 organizations that received the award this year from the Wisconsin DNR (Department of Natural Resources) in

recognition of outstanding efforts to recycle and reduce waste. CCP’s award falls under the category of “Projects and Initiatives” that have led to the recycling of more material and/or better recycling cost-effectiveness.

In addition to sourcing most of its paper rolls from recycled content, CCP’s specialty is applying a corrosion-inhibiting coating that allows the paper to be recycled after use. This is an important environmental benefit for manufacturers and distributors that use Cortec ® VpCI ® Paper to package and

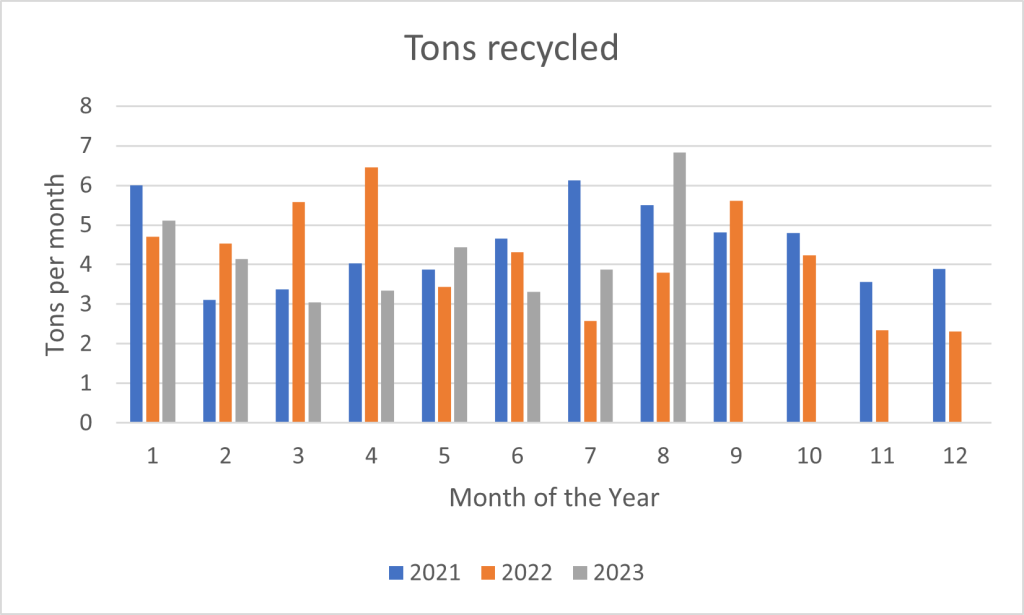

protect metal parts in a variety of industries. It is also an advantage for CCP’s waste-handling processes. Converting its coated VpCI ® Papers into marketable rolls and different sizes of sheeting inevitably leaves behind a large amount of paper scrap. CCP collects the scrap, compacts it into bales, and sends it to a recycling broker that sorts and resells the scrap to various paper/recycling plants. Cortec ® Environmental Specialist, Derek Jensen, estimates that since 2017, CCP has recycled 616 tons of paper, equal to approximately 12,320 trees saved!

Cortec ® is honored to receive this award, which underscores the company’s strong commitment to

recycling, waste reduction, and sustainability in the quest for practical solutions to corrosion. Learn more

about the award here!

Keywords: Cortec, Cortec Coated Products, Wisconsin recycling excellence award, recycled paper, what to do with paper scrap, Cortec environmental commitment, reduce waste, Wisconsin DNR, corrosion-inhibiting paper, corrosion protection