High-quality standards, 3-year warranty, customization, and a wide range of executions and accessories are some of the features of the service and of the wide range of Rossi S.p.A. planetary gear reducers and gear motors. High-performance “ready to use” technologies, without compromise and without waste, combined with a flexible and dynamic service, able to satisfy all the needs in different application sectors. When it comes to high-performance, high-precision gear manufacturing and machining, quality technology, cutting-edge technology, and experience are the keys to reliable solutions.

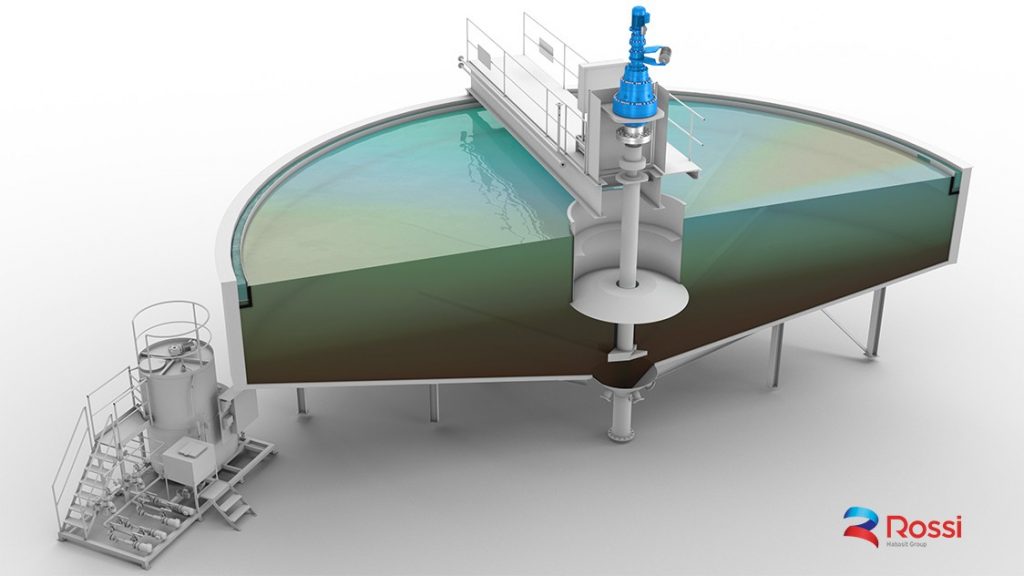

Planetary gearboxes are applicable in different industrial sectors and their use is linked to the advantages they offer in some particular applications, for example the high reduction ratio, which compared to helical and bevel helical gearboxes, allows to reach higher performances. They are extremely compact gearboxes particularly suitable for high torque and loads to be supported, therefore suitable for heavy duty environments and where it is necessary to support considerable loads: from the mining to the iron and steel industry, from the marine to the food industry.

EP Series planetary gearboxes are suitable to support high axial and radial loads, and while traditional designs can only be stressed in one direction, planetary systems are better able to withstand loads in all directions. They are compact and equipped with small gears that, at the same speed of rotation, are able to compete, at noise level, with the gears of traditional helical teeth reduction gears.

A wide range, with a range of 24 sizes, characterized by a nominal moment (MN2) up to 3,000,000 Nm and a transmission ratio starting from (iN) 3.55, in line (EL) or right angle (EB) configuration highly customizable to better suit specific industrial applications. Modularity can be considered the foundation of Rossi production. The flexibility of the product and the modular architecture allow, starting from standard products, to assemble different, customized products and design modular solutions that can be integrated with each other such as combined units and control units, including the most varied and demanding application requirements, including the “Heavy Industry” marked by high power and reliability. This modular approach ensures faster delivery times and allows you to have turnkey products within two weeks from ordering.

All EP Series gearboxes are delivered pre-tested, painted and protected against corrosion and complete with PAO-based synthetic oil (from range 001 to 021). The customer will therefore incur lower initial costs, saving time in operations that would take several hours before start-up and postponing the first scheduled maintenance.

Accurate constructive peculiarities favor the execution of gearboxes with reduced backlash on the output shaft, widely used on precision drives, helping to increase reliability and durability; shafts and gears in casehardened and tempered or nitrided steel. Straight bevel gears and GLEASON spiral bevel gears with ground profile. Nodular cast iron and/or cast steel supports and planetary carriers, bearings and oil seals of primary brands.

High-performance products with longer lubrication intervals and therefore easy and deferred maintenance. The wide range of accessories and design for each size, such as static and hydraulic brakes, backstop device, fan cooling and water cooling, complete the modularity and flexibility of a technology that is not only efficient but also the result of constant development in full synergy with the demands of the market and customers.

All EP gearboxes can be supplied with the EU declaration of conformity to the ATEX directive (Directive 2014/34/EU for equipment intended for use in potentially explosive atmospheres), furthermore the whole range has obtained the DNV GL “TYPE APPROVAL CERTIFICATE” valid for all specific marine applications.

The two Rossi production facilities in Lecce, Italy, dedicated to the EP Series planetary gearboxes range, equipped with the latest generation precision machining technologies and Industry 4.0, are production excellence. An advanced production alongside a Technical Sales Support of great experience to follow customers from the design phase and develop, where necessary, highly customized engineering solutions, advanced and compact design or alternatively to choose the best combination of products in the catalog for the single application. Rossi is present in almost all the countries of the world through a widespread sales and assistance network organized through branches and distributors, always close to the customer, from pre-sales consulting to sales, installation, and technical assistance.