GEA completes the T.VIS® control top series with a version for potentially explosive processes: GEA T.VIS® E-20 is of interest to the dairy industry, among others, which processes highly flammable hazardous substances in the form of milk powder and sugar dust – for example in the production of fruit preparations.

In the food, dairy, chemical and pharmaceutical industries, where powders and liquids are processed, gas and dust explosions are among the greatest production hazards. Examples of highly flammable substances include alcohols, dyes and hydrocarbons, but can also be found in everyday products such as flour, pudding powder, instant coffee, sugar, milk powder, potato and soup powder.

Ex-compliant status visualization

“Usually, fine dust is produced when solid materials are ground. When this comes into contact with oxygen, even small amounts of energy are sufficient to cause ignition,” explains Product Manager Bernd Porath, who is in charge of valve controls at GEA. Accordingly, manufacturers must protect their equipment from explosion (“Ex”) hazards. For valves controlling the flow of products at the interfaces between important process steps, it is all the more important to adapt all components and functions to the challenge of operational reliability. Every new development must pass global Ex certification. “For example, manufacturers want to identify the status of a valve at a glance. Therefore, we developed an Ex-compliant status indication. We use LEDs with limited ignition energy that glow like a star in the hood of the control top, clearly indicating the active position.”

Improved shock resistance

Like all control tops of the T.VIS family, the new Ex-protected version has a very compact design. The low installation height of only 160 millimeters facilitates installation and maintenance. The T.VIS E-20 also does without the switch rod, which was still used in the predecessor model GEA SES for the mechanical status indicator of the valve. Since it protruded from the hood, it required a lot of installation space. Along with the new GEA T.VIS M-20 control top generation, the shock resistance has more than doubled to 10 g. For example, internal spring-loaded terminals secure the electrical connections under heavy stress caused by vibrations.

Thanks to the T.VIS housing technology, all components feature the highest level of dust and moisture protection according to the IP6k9k standard. GEA also converted the internal pilot valves to tappet technology. Compared to diaphragms that are prone to cracking, this offers better sealing performance and a very long service life.

Novelty: suitable for global use

GEA T.VIS E-20 is one of the first Ex-protected control tops on the market that has all major approvals for use in potentially explosive atmospheres worldwide. “Previously, our customers had to go through the complex legal requirements applicable to their process technology in potentially explosive areas separately for each region. We’ve taken the hassle away from them and now offer our Ex-protected control top with documented spec sheet for global use.” This includes, for example, ATEX and UKEx for Europe, as well as the international IECEx system, which is also the basis for certification according to CCCEx in China. GEA expects the T.VIS E-20 to be approved for the North American market this year.

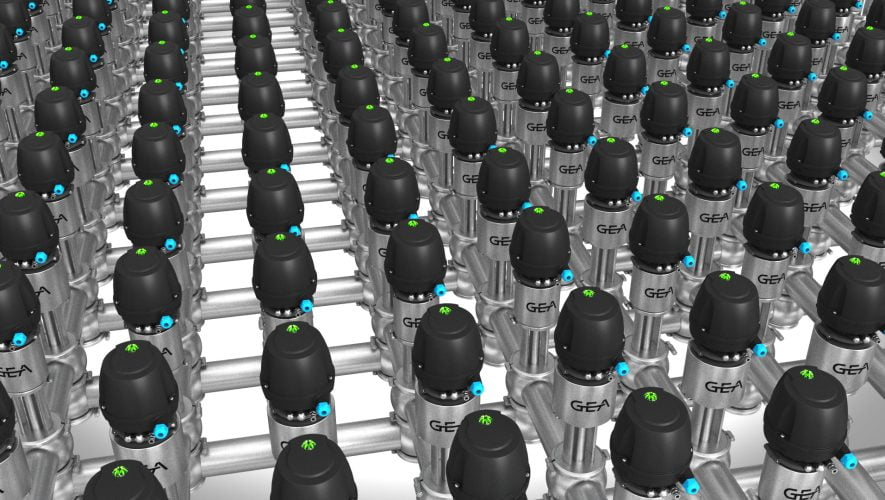

Fig. 1: GEA completes the T.VIS® control top series with a version for potentially explosive processes: GEA T.VIS E-20 has all major approvals for use in potentially explosive atmospheres worldwide. Source: GEA

Fig. 2: The shock resistance of the GEA T.VIS E-20 has more than doubled to 10 g. Source: GEA

Fig. 3: Ex-compliant status indication: GEA T.VIS E-20 uses LEDs with limited ignition energy that glow like a star in the hood of the control top. The green light indicates the active position. Source: GEA