SIG today announced that it will construct a new plant in Queretaro, Mexico to serve North American markets. The plant will further expand SIG’s global production network and will enable the company to build on its strong track record of growth in North America.

Through its existing sales and service presence, SIG has been able to forge strong relationships with major dairies in Mexico, a large and growing milk market. In the USA, SIG has a well-established co-manufacturing customer base and is ideally placed to serve innovative and expanding new categories.

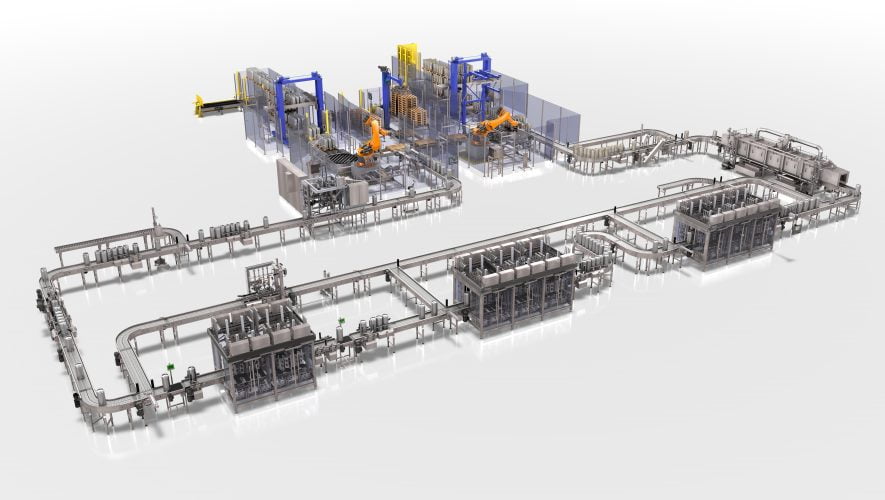

SIG will invest around €40 million in the new plant over the period 2021-2023. The investment will cover state-of-the art production capacity for the printing, cutting and finishing of carton packs. The plant is expected to open in the first quarter of 2023 and will create around 200 jobs. It will have a highly flexible layout with a focus on ergonomics and the environment. Land and buildings will be financed through a long-term lease with an NPV of approximately €20 million.

Ricardo Rodriguez, President & General Manager Americas, said: “We are very excited to announce this project which will enable us to serve our North American customers faster and more efficiently. Delivery lead times will be reduced and we will be able to respond rapidly to changes in demand. Our new plant will further drive growth in the region while demonstrating our commitment to the highest environmental standards.”