Bio-based coatings are rapidly gaining market share due to their effectiveness, lower cost and environmental profile. They are biodegradable and in most cases do not need removal before painting or welding, providing far more economical solution than traditional petroleum derived rust preventives that require expensive degreasers and hazardous disposal. The hazards in conventional anticorrosion coatings have led to surge in government regulations that have restrained anticorrosion coatings market growth. Market trends are moving towards sustainable and renewable materials as community is becoming more aware of importance of utilizing environmentally safe solutions.

Extensive research has enabled Cortec® to create solutions that successfully replace hazardous chemicals such as BioCorr HP. The company offers ecologically safe corrosion control solutions whose performance has outgrown

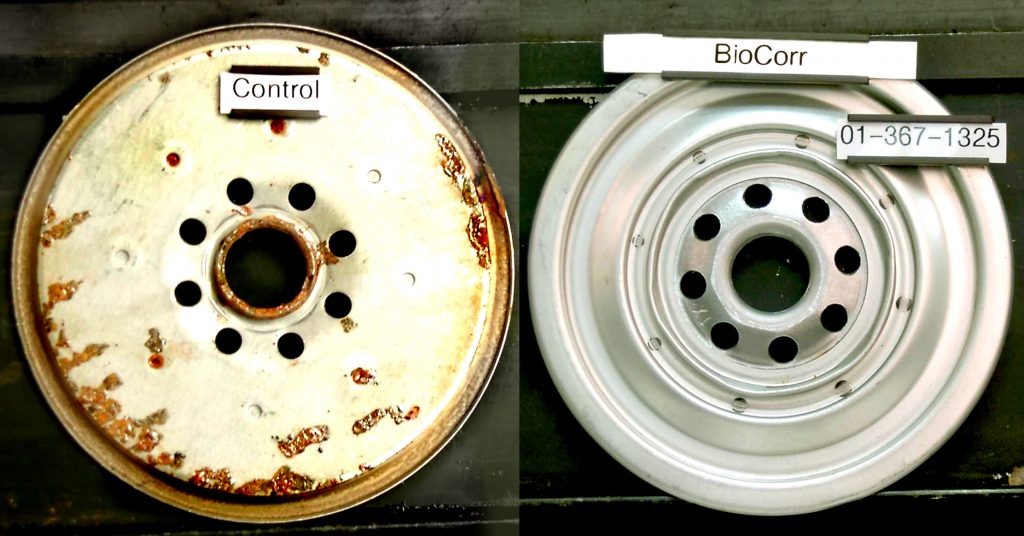

conventional rust preventatives. Not only are these bio-based, environmentally safe alternatives functionally superior to conventional petroleum-derived products, but they provide a far more economical solution. In addition to offering end-users excellent environmental profile, superior corrosion protection, BioCorr® is typically 40 percent less expensive than its petroleum counterparts. BioCorr® HP is a new generation of BioCorr®, Cortec’s time-tested water-based and biobased rust preventative containing 54% USDA certified biobased content. It is designed to preserve metals in storage and during transportation. This ready-to-use product has excellent emulsion stability, contains no chemicals that interfere with automatic transmission fluids, provides multi-metal protection, and is an excellent environmentally sound alternative to petroleum-derived products due to its biobased content. It protects for up to two years of indoor storage or during shipments when combined with VpCI® packaging materials. The product uses a unique UV-marker technology for easier identification on the metal surface. BioCorr® HP Rust Preventative is a USDA Certified Biobased Product. BioCorr® HP can be used for storage and shipment of metal parts such as: automotive components (specifically designed for use with transmissions), pipes, flanges and gears as well as sheets, coils, and castings.

More Benefits

- Displaces water and oil from metal surfaces

- Cost effective

- Odor free and forms an invisible dry-to-touch film helping to create a clean workplace and prevents material waste

- Streamlines processes by not requiring removal in most cases

A comprehensive study on Cortec’s BioCorr® rust preventative was conducted in collaboration with Laboratory for Materials Protection at University of Zagreb. The paper covered economic and environmental impact of traditional rust preventatives versus bio-based product. The study includes comparative experimental investigation of biobased and petroleum based rust preventives in humidity chamber, with the corrosion protection efficiency being determined using various polarisation techniques. In this paper the corrosion parameters as well as economic and environmental properties of five different rust preventatives are used for temporary corrosion protection. Specifically, water/biobased was compared to petroleum based products. The results of the study showed that in addition to being more environmentally friendly, biobased rust preventatives offer optimal corrosion protection, with no increase in protection cost, compared to petroleum-based and hazardous rust preventatives.